World-Leading Brands Use HOD UV

Bottlers the world over rely on the water treatment and UV experts at Atlantium to provide non-chemical disinfection and biofouling control solutions.

Chemical-Free, Sustainable Solution Saves Energy and Water

Save money, reduce energy costs, use fewer chemicals and guarantee biosecure water to protect your brand. Atlantium Technologies is eager to show you how to increase efficiency, meet regulatory requirements and ensure biosecurity. UV is approved for heat pasteurization of water and Atlantium’s HOD UV technology is able to reduce those energy costs by up 50% or more.

For inquiries, contact us at [email protected].

Proven Treatment with Guaranteed Results

- No changes to taste and flavor profiles

- Real-time monitoring & control

- Push-of-a-button compliance reports

- Validated according to U.S. EPA criteria to undetectable microbial level in 1000ml

Atlantium Hydro-Optic (HOD) UV Bottling Solutions

Why HOD UV?

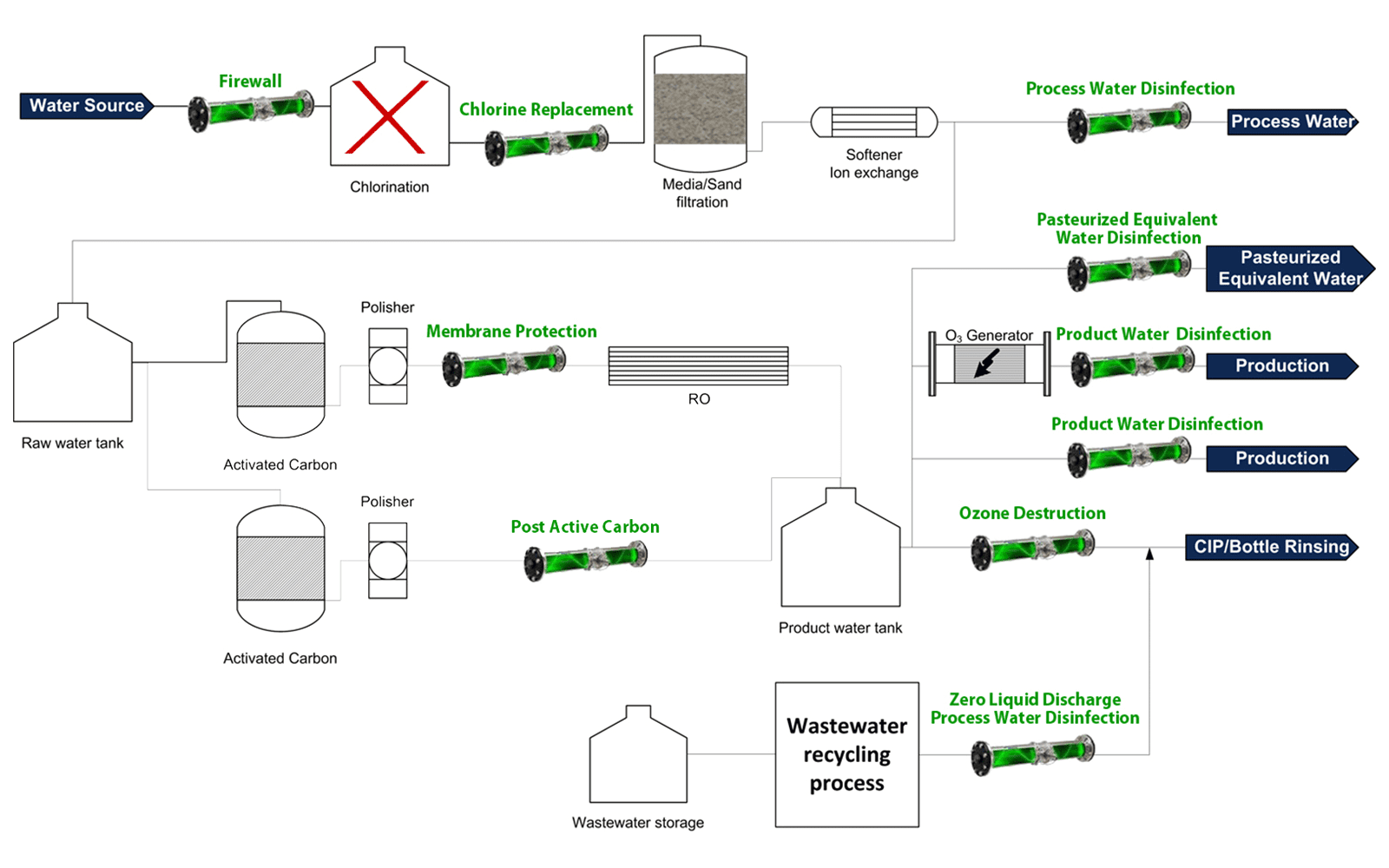

HOD UV is a sustainable alternative to chlorine and ozone disinfection. With accredited validation to undetectable microbial level in 1000ml, it easily inactivates microorganisms including chlorine resistant viruses, pseudomonas, cryptosporidium and giardia, as well as algae. HOD UV eradicates the threat of disinfection by-products that could result in product recall and the physical process for disinfection does not affect water mineral balance and flavor profile.

HOD UV has field-proven experience treating water contaminated with algae, ensuring that bottled water remains clear and won’t turn green from algae contamination, ensuring a much longer shelf life.

Municipal source water or alternative groundwater sources cannot guarantee water safety 24/7. As a result, disinfection is required at the entrance to the plant to ensure product safety and prevent contaminated water from entering the production line.

HOD UV inhibits biofilm growth on membranes, greatly extending membrane life and reducing the maintenance burden and operating costs. Membrane biofouling reduces production and increases the energy required to push the water through the membrane.

Ozone is a strong oxidant that changes the flavor profile of bottled beverages and needs to be removed. HOD UV is an efficient, cost-effective solution for ozone destruction.

What Our Customers Say About Us

“We have a long history in our company of maintaining treatment systems and production methods that are at the cutting edge of our industry. For that reason, Roaring Spring has partnered with Atlantium Technologies to help us meet the new 4-log* standard of EPA. This treatment system is automated and will not allow any water out into our distribution system that does not meet the standards, and we’re very proud to be a partner with Atlantium Technologies.”

— Mr. Scott Hoover, General Manager Roaring Spring Water, and President of IBWA

Hydro-Optic™ UV Water Biosecurity and Safety

Atlantium’s Hydro-Optic™ (HOD) UV technology guarantees process control and water safety without the use of chemicals; as a result, there is no residual taste or odor to affect product flavor. Validated to regulatory standards for EPA and FDA with accredited validation to undetectable microbial level in 1000ml, HOD UV provides effective disinfection and biofouling control through automated operation and compliance reporting.

A Highly Efficient Non-Chemical Disinfection Solution for Bottlers

Atlantium Technologies’ Hydro-Optic™ (HOD) UV is a proven and highly efficient, sustainable alternative to chlorine and ozone disinfection. The HOD UV technology guarantees process control and water safety without the use of chemicals; as a result, there is no residual taste or odor to affect product flavor. Validated to regulatory standards for EPA and FDA with accredited validation to undetectable microbial level in 1000ml, HOD UV provides effective disinfection and biofouling control through automated operation and compliance reporting.