An Efficient Treatment Solution Lowers Power & Operating Costs

The HOD UV technology provides an advanced and highly efficient disinfection and dechlorination treatment solution for power plants, using medium pressure UV light without the use of chemical disinfectants.

HOD UV helps lower operating costs by protecting boiler feed make-up water from bacterial growth and associated biofouling; extend micron filter and RO membrane life; improve heat exchanger performance; and improve permeate quality and quantity with a proven solution.

For inquiries, contact us at info@atlantium.com.

Why HOD UV?

Every HOD UV system comes equipped with an intuitive, user-friendly and comprehensive control interface to track system operation in real-time, provide operators with live data on the operation of their system, and automatically generates compliance reporting.

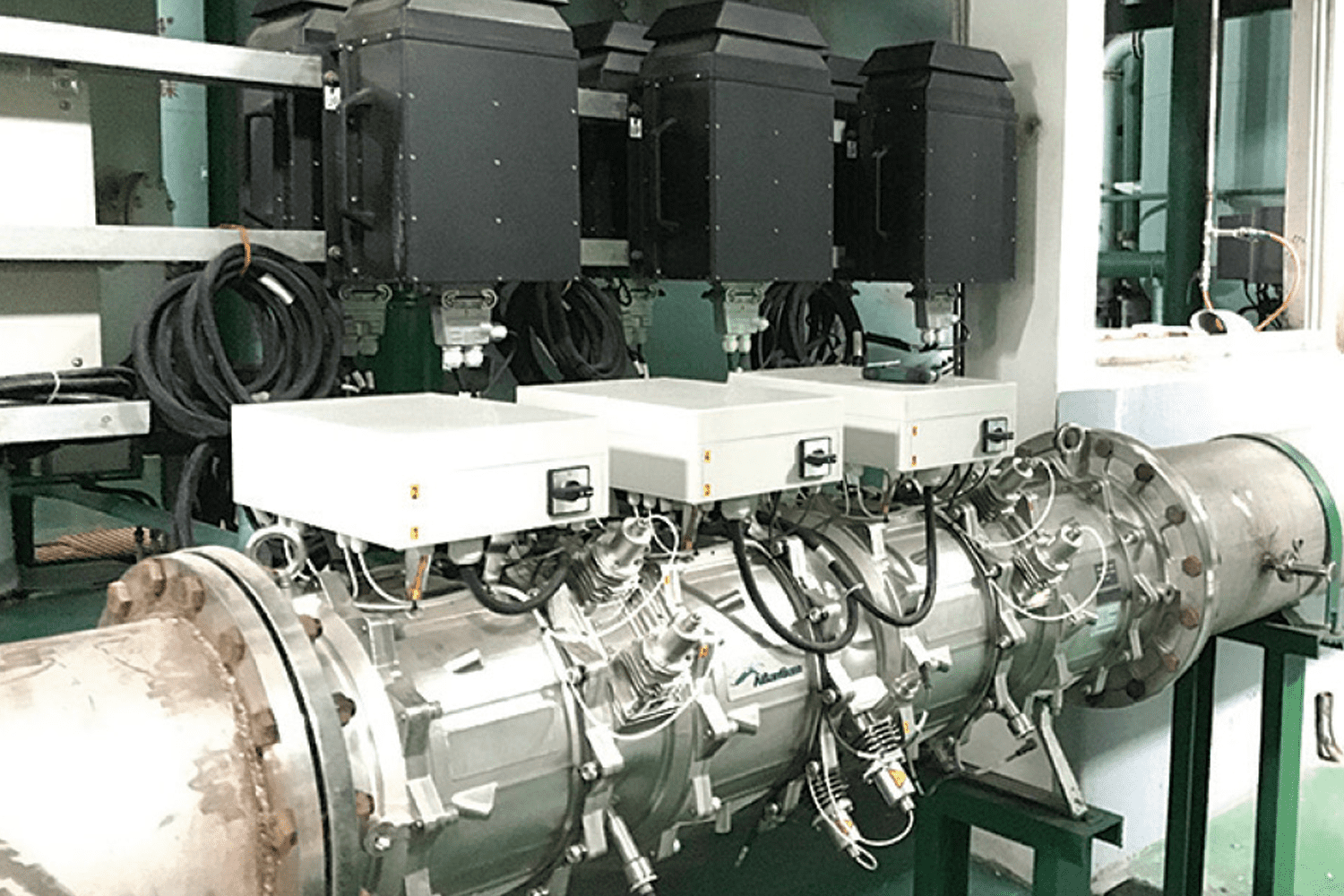

The HOD UV system uses a proprietary Total Internal Reflection (TIR) based design, coupled with the comprehensive monitoring of critical parameters unique to Atlantium, to allow the system to achieve and maintain the specified UV dose for application specific needs.

The system’s patented TIR technology, which is similar to fiber optic science, recycles UV light energy within the HOD UV chamber. The core of the technology is its chamber made of high-quality quartz surrounded by an air block instead of traditional stainless steel This configuration uses fiber optic principles to trap the UV light photons and recycle their light energy. The photons repeatedly bounce through the quartz surface back into the chamber, effectively increasing their paths and their opportunities to inactivate microbes.

HOD UV systems are available to operate under a range of water quality conditions, including low percent UVT. UV Transmittance (UVT) is an indicator of water quality and designates the percentage of UV light that passes through the water. HOD UV allows clients to eliminate the use of biocides and achieve non-chemical disinfection or dechlorination by employing an easy-to-use and maintain system.

The HOD UV technology is a physical process for disinfection that exposes bacteria, viruses and protozoa to germicidal wavelengths of UV light, measured in nanometers (nm), to render them incapable of reproducing or further infecting a water system. UV light can destroy chemical contaminants through a process called UV oxidation.

The HOD UV technology is equipped with medium-pressure (MP) UV lamps that provide polychromatic UV light (200-415 nm) to enable the production of a high-density broad-spectrum UV light that can inactivate a range of bacteria, viruses and organisms. The light emitted by MP lamps is within the absorption spectrum of FAC (200-360 nm), making it the ideal for dechlorination applications.

The HOD UV technology has consistently achieved FAC levels below 0.01 ppm, or non-detect levels, in full-scale commercial application with some systems operating for more than six years with extraordinary results. The HOD UV technology is unique in its ability to disinfect and dechlorinate in a single, non-chemical process.

Atlantium Hydro-Optic (HOD) UV Power Solutions

EPRI 2019 Generation Technology Transfer Award Presented to Plant Bowen

Aaron Nickles, System Owner, Southern Company – Plant Bowen, and Tracy Underwood, Lab Team Leader, Southern Company – Bowen Georgia Power Company received the 2019 Electric Power Research Institute (EPRI) Generation Technology Transfer Award for Plant Bowen’s boiler feed water dechlorination using Atlantium’s HOD UV.

Power Plant in Pinghu, China Installs HOD UV for Non-Chemical Disinfection of Boiler Feed Make-Up Water

A power plant in Pinghu, located within the Zhejiang Province, China, installed the HOD UV treatment system to replace the use of chemical biocides and protect boiler feed make-up water from anaerobic and aerobic bacterial growth and associated biofouling. The facility has achieved non-chemical boiler-feed make-up water disinfection using the HOD UV technology.