Applications

- AOP

- Drinking Water Treatment

- Reuse Water Treatment

- Open Channel

- Wastewater Treatment

For inquiries, contact us at info@atlantium.com.

A Validated Solution

for Microbial and Virus* Inactivation

Water treatment plants can achieve water biosecurity with the use of light and without the use of chemical disinfectants, with the HOD™ (Hydro-Optic Disinfection) UV technology that is validated to regulatory standards with accredited validation to undetectable microbial level in 1000ml . HOD UV provides effective disinfection and biofouling control, automated operation and compliance reporting is available to support facilities.

With Atlantium, even small systems can afford large-system technology and performance. The small footprint, modular design and extensive validated envelope of operation means a sustainable solution with instant reports documented and verified in real time.

*Organism surrogates (MS2, QB, and T1UV) and adenovirus. See Validation test certification.

Atlantium Hydro-Optic (HOD) UV Municipal Solutions

What Our Customers Say About Us

“Based on the proposals, life-cycle costs at two projected water demand growth rates were estimated including initial purchase and installation, energy and bulb replacement.

Other key selection considerations included: UV system controls and software; ability to fit within the limited existing, available WTP space; ease of system calibration; type of bulb cleaning system; system head loss; technical support availability; and operator requirements.

…The Town selected the Atlantium system. Their system is more compact given the WTP space constraints; offers the greater reliability of a dual-train configuration; an ultrasonic cleaning system rather than a mechanical wiper system; and the possibility that a medium-pressure system is more effective for virus* inactivation than the low-pressure systems …”

Excerpt from ACE 2014 poster session “Controlling Disinfection Byproducts in a Slow Sand Filtration Plant” by Mr. David F. Edson, P.E., Sr. VP, Hoyle, Tanner & Associates, Inc., Consulting Engineers for the Town of Hillsborough.

*Organism surrogates (MS2, QB, and T1UV) and adenovirus. See Validation test certification.

Why Hydro-Optic™ UV?

- Third-party validation

- Accredited validation to undetectable microbial level in 1000ml

- Validated and proven using real Adenovirus, not surrogate

*Organism surrogates (MS2, QB, and T1UV) and adenovirus. See Validation test certification.

- Physical disinfection process

- Protect water sources without the reliance on chemical disinfectants and their associated risks (e.g., safety, storage, chain of supply, handling, and formation of carcinogenic DBPs)

- Easily inactivates chlorine-resistant pathogens like cryptosporidium, giardia and pseudomonas

*Organism surrogates (MS2, QB, and T1UV) and adenovirus. See Validation test certification.

- Instantaneous disinfection on-demand

- In-line compact solution integrates into almost any footprint

- Real-time tracking and monitoring provides early warning to avoid impending anomalies

- Compliance reports generated automatically

- Reduced operational and maintenance costs

- Reduced chemical use minimizes biofouling and pipe corrosion

- Reduced carbon footprint

Can We Use Adenovirus Validated Ultraviolet Systems for Inactivation of SARS-CoV-2, The Virus* That Causes COVID-19?

This paper discusses evidence for SARS-CoV-2 (the virus* that causes COVID-19) in water and the possibility of using UV systems for its disinfection, providing information regarding the ability of a UV system validated to undetectable microbial level in 1000ml per the U.S. EPA guidelines with adenovirus to effectively mitigate SARS-CoV-2 in water.

*Organism surrogates (MS2, QB, and T1UV) and adenovirus. See Validation test certification.

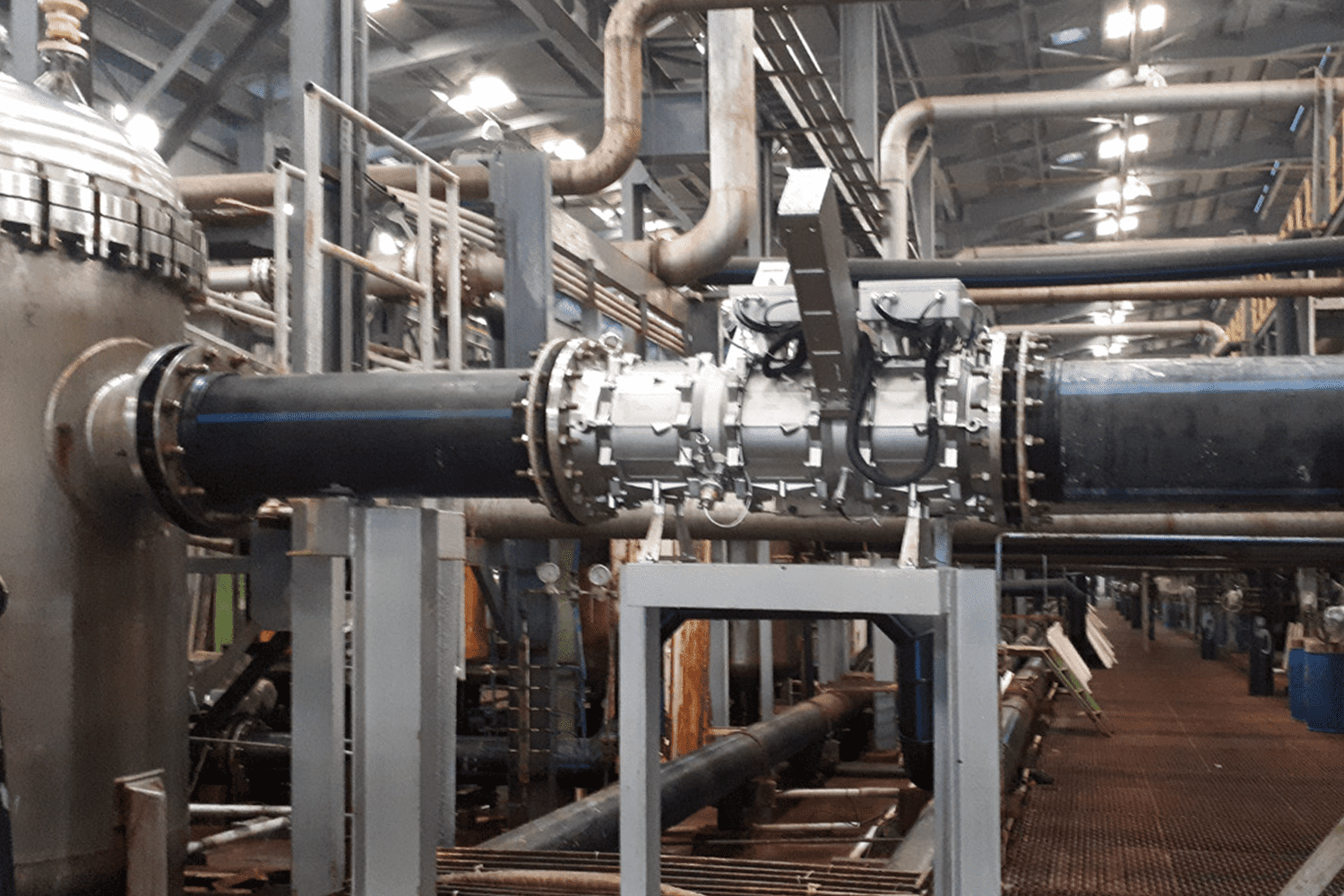

Seawater RO Facility in Asia Optimizes Membrane Performance with HOD UV Technology

A seawater reverse osmosis (SWRO) facility in Asia with a 100,000 m3 per day drinking water capacity undertook a comparative study to evaluate the disinfection efficacy of the HOD UV technology to provide enhanced protection of the RO elements and positively affect overall RO system and facility performance. Following the installation of the HOD UV technology, the facility experienced significant operational improvements.